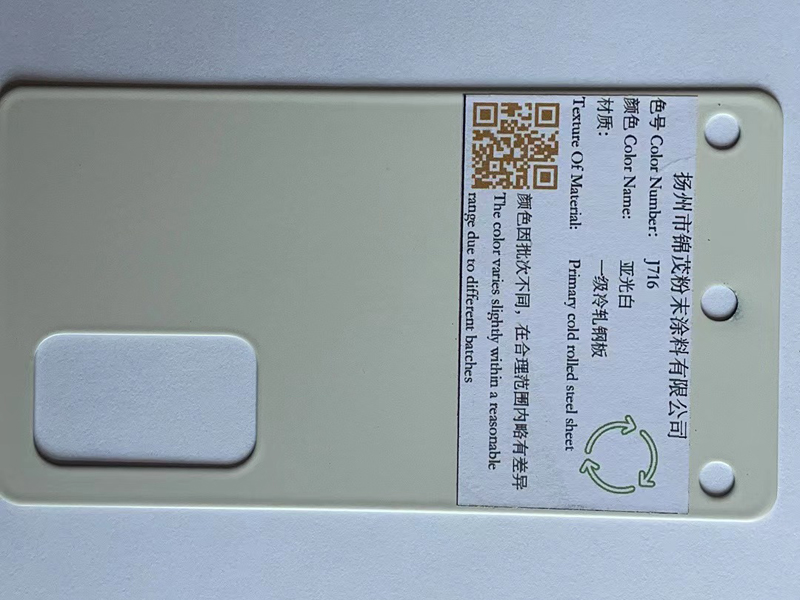

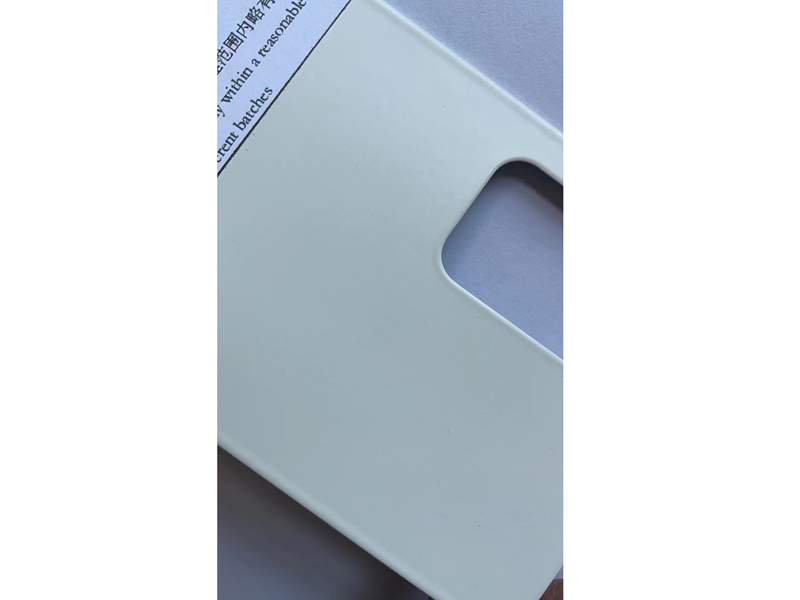

J716 white matt

Previous

J9002 white orange pattern

PRODUCT

-

9005 black sand patternThe advantages of powder coating are many. The first is to paint the bento, and there is no peculiar smell after being painted on the wall like other paints, and it is not easy to dry, the paint is very easy to dry, and at the same time, it will not have peculiar smell after being applied, and it will not be harmful to the human body. constitute damage or cause related diseases. Secondly, the electrostatic coating can be recycled, is a recyclable material, will not be wasted, saves the country's resources and can improve the pollution level of the environment. It is a new type of green coating. Compared with powder coatings, everyone likes green, environmentally friendly, non-toxic and harmless coatings. It can be rich and colorful to our society, and yet poses no harm to our environment. Environmentally friendly powder coating has entered our green family with its characteristics, so that it can be developed faster and faster.9005 black sand pattern0.00The advantages of powder coating are many. The first is to paint the bento, and there is no peculiar smell after being painted on the wall like other paints, and it is not easy to dry, the paint is very easy to dry, and at the same time, it will not have peculiar smell after being applied, and it will not be harmful to the human body. constitute damage or cause related diseases. Secondly, the electrostatic coating can be recycled, is a recyclable material, will not be wasted, saves the country's resources and can improve the pollution level of the environment. It is a new type of green coating. Compared with powder coatings, everyone likes green, environmentally friendly, non-toxic and harmless coatings. It can be rich and colorful to our society, and yet poses no harm to our environment. Environmentally friendly powder coating has entered our green family with its characteristics, so that it can be developed faster and faster.

9005 black sand patternThe advantages of powder coating are many. The first is to paint the bento, and there is no peculiar smell after being painted on the wall like other paints, and it is not easy to dry, the paint is very easy to dry, and at the same time, it will not have peculiar smell after being applied, and it will not be harmful to the human body. constitute damage or cause related diseases. Secondly, the electrostatic coating can be recycled, is a recyclable material, will not be wasted, saves the country's resources and can improve the pollution level of the environment. It is a new type of green coating. Compared with powder coatings, everyone likes green, environmentally friendly, non-toxic and harmless coatings. It can be rich and colorful to our society, and yet poses no harm to our environment. Environmentally friendly powder coating has entered our green family with its characteristics, so that it can be developed faster and faster.9005 black sand pattern0.00The advantages of powder coating are many. The first is to paint the bento, and there is no peculiar smell after being painted on the wall like other paints, and it is not easy to dry, the paint is very easy to dry, and at the same time, it will not have peculiar smell after being applied, and it will not be harmful to the human body. constitute damage or cause related diseases. Secondly, the electrostatic coating can be recycled, is a recyclable material, will not be wasted, saves the country's resources and can improve the pollution level of the environment. It is a new type of green coating. Compared with powder coatings, everyone likes green, environmentally friendly, non-toxic and harmless coatings. It can be rich and colorful to our society, and yet poses no harm to our environment. Environmentally friendly powder coating has entered our green family with its characteristics, so that it can be developed faster and faster. -

7015D matt medium gray(1) In order to give full play to the characteristics of powder coating and prolong the service life of the coating film. (2) When spraying, the object to be coated must be completely grounded to increase the spraying efficiency of powder coating.7015D matt medium gray0.00(1) In order to give full play to the characteristics of powder coating and prolong the service life of the coating film. (2) When spraying, the object to be coated must be completely grounded to increase the spraying efficiency of powder coating.

7015D matt medium gray(1) In order to give full play to the characteristics of powder coating and prolong the service life of the coating film. (2) When spraying, the object to be coated must be completely grounded to increase the spraying efficiency of powder coating.7015D matt medium gray0.00(1) In order to give full play to the characteristics of powder coating and prolong the service life of the coating film. (2) When spraying, the object to be coated must be completely grounded to increase the spraying efficiency of powder coating. -

7037 Matt light gray, The product is non-toxic, non-solvent and non-volatile toxic substances, so there is no pollution, no fire, no "three wastes" discharge and other public hazards, and fully meets the requirements of the National Environmental Protection Law.7037 Matt light gray0.00, The product is non-toxic, non-solvent and non-volatile toxic substances, so there is no pollution, no fire, no "three wastes" discharge and other public hazards, and fully meets the requirements of the National Environmental Protection Law.

7037 Matt light gray, The product is non-toxic, non-solvent and non-volatile toxic substances, so there is no pollution, no fire, no "three wastes" discharge and other public hazards, and fully meets the requirements of the National Environmental Protection Law.7037 Matt light gray0.00, The product is non-toxic, non-solvent and non-volatile toxic substances, so there is no pollution, no fire, no "three wastes" discharge and other public hazards, and fully meets the requirements of the National Environmental Protection Law. -

M22-0424 red sand pattern1.2 Polyester powder coating. Polyester powder coatings share common properties with other types of powder coatings. The performance of weather resistance and UV resistance is better than epoxy resin. In addition, because polyester resin has polar groups, the powder rate is higher than that of epoxy resin, it is not easy to yellow during the baking process, has high gloss, good leveling, full paint film, light color and other characteristics. Very decorative. Generally used in refrigerators, washing machines, vacuum cleaners, instrument housings, bicycles, furniture and other fields.M22-0424 red sand pattern0.001.2 Polyester powder coating. Polyester powder coatings share common properties with other types of powder coatings. The performance of weather resistance and UV resistance is better than epoxy resin. In addition, because polyester resin has polar groups, the powder rate is higher than that of epoxy resin, it is not easy to yellow during the baking process, has high gloss, good leveling, full paint film, light color and other characteristics. Very decorative. Generally used in refrigerators, washing machines, vacuum cleaners, instrument housings, bicycles, furniture and other fields.

M22-0424 red sand pattern1.2 Polyester powder coating. Polyester powder coatings share common properties with other types of powder coatings. The performance of weather resistance and UV resistance is better than epoxy resin. In addition, because polyester resin has polar groups, the powder rate is higher than that of epoxy resin, it is not easy to yellow during the baking process, has high gloss, good leveling, full paint film, light color and other characteristics. Very decorative. Generally used in refrigerators, washing machines, vacuum cleaners, instrument housings, bicycles, furniture and other fields.M22-0424 red sand pattern0.001.2 Polyester powder coating. Polyester powder coatings share common properties with other types of powder coatings. The performance of weather resistance and UV resistance is better than epoxy resin. In addition, because polyester resin has polar groups, the powder rate is higher than that of epoxy resin, it is not easy to yellow during the baking process, has high gloss, good leveling, full paint film, light color and other characteristics. Very decorative. Generally used in refrigerators, washing machines, vacuum cleaners, instrument housings, bicycles, furniture and other fields. -

8300S coffee sand grain1. Thermosetting powder coating refers to the use of thermosetting resin as a film-forming substance, and the curing agent participating in the cross-linking reaction can form an insoluble and infusible hard coating after heating. No matter how high the temperature is, the coating will not soften like a thermoplastic coating, but can only be synthesized. Since the resin used in the thermosetting powder coating is a prepolymer with a lower degree of polymerization and a lower molecular weight, the coating has better leveling and better decoration, and the low molecular weight prepolymer is cured. It can form macromolecules of network cross-linking, so the coating has better corrosion resistance and mechanical properties. Therefore, the development of thermosetting powder coatings is particularly fast.8300S coffee sand grain0.001. Thermosetting powder coating refers to the use of thermosetting resin as a film-forming substance, and the curing agent participating in the cross-linking reaction can form an insoluble and infusible hard coating after heating. No matter how high the temperature is, the coating will not soften like a thermoplastic coating, but can only be synthesized. Since the resin used in the thermosetting powder coating is a prepolymer with a lower degree of polymerization and a lower molecular weight, the coating has better leveling and better decoration, and the low molecular weight prepolymer is cured. It can form macromolecules of network cross-linking, so the coating has better corrosion resistance and mechanical properties. Therefore, the development of thermosetting powder coatings is particularly fast.

8300S coffee sand grain1. Thermosetting powder coating refers to the use of thermosetting resin as a film-forming substance, and the curing agent participating in the cross-linking reaction can form an insoluble and infusible hard coating after heating. No matter how high the temperature is, the coating will not soften like a thermoplastic coating, but can only be synthesized. Since the resin used in the thermosetting powder coating is a prepolymer with a lower degree of polymerization and a lower molecular weight, the coating has better leveling and better decoration, and the low molecular weight prepolymer is cured. It can form macromolecules of network cross-linking, so the coating has better corrosion resistance and mechanical properties. Therefore, the development of thermosetting powder coatings is particularly fast.8300S coffee sand grain0.001. Thermosetting powder coating refers to the use of thermosetting resin as a film-forming substance, and the curing agent participating in the cross-linking reaction can form an insoluble and infusible hard coating after heating. No matter how high the temperature is, the coating will not soften like a thermoplastic coating, but can only be synthesized. Since the resin used in the thermosetting powder coating is a prepolymer with a lower degree of polymerization and a lower molecular weight, the coating has better leveling and better decoration, and the low molecular weight prepolymer is cured. It can form macromolecules of network cross-linking, so the coating has better corrosion resistance and mechanical properties. Therefore, the development of thermosetting powder coatings is particularly fast. -

J9005 Silver flower on black backgroundDifferent from the film-forming mechanism of ordinary powder coatings, the film-forming process of UV-curable powder coatings is: heating with infrared rays or hot air to melt and level the powder coatings, and then stop the photopolymerization reaction under the irradiation of ultraviolet light, and cure to form a film. In this process, the melting process of the powder coating is completely separated from the curing process, which is easy to control and the appearance of the coating film is smooth.J9005 Silver flower on black background0.00Different from the film-forming mechanism of ordinary powder coatings, the film-forming process of UV-curable powder coatings is: heating with infrared rays or hot air to melt and level the powder coatings, and then stop the photopolymerization reaction under the irradiation of ultraviolet light, and cure to form a film. In this process, the melting process of the powder coating is completely separated from the curing process, which is easy to control and the appearance of the coating film is smooth.

J9005 Silver flower on black backgroundDifferent from the film-forming mechanism of ordinary powder coatings, the film-forming process of UV-curable powder coatings is: heating with infrared rays or hot air to melt and level the powder coatings, and then stop the photopolymerization reaction under the irradiation of ultraviolet light, and cure to form a film. In this process, the melting process of the powder coating is completely separated from the curing process, which is easy to control and the appearance of the coating film is smooth.J9005 Silver flower on black background0.00Different from the film-forming mechanism of ordinary powder coatings, the film-forming process of UV-curable powder coatings is: heating with infrared rays or hot air to melt and level the powder coatings, and then stop the photopolymerization reaction under the irradiation of ultraviolet light, and cure to form a film. In this process, the melting process of the powder coating is completely separated from the curing process, which is easy to control and the appearance of the coating film is smooth. -

S16-54 black background copper flowerThe factors that affect the leveling of powder coatings mainly include three aspects. One is leveling aids. Appropriate leveling aids, such as silicone resins, polyacrylate resins and fluororesins, are added to the formula of powder coatings. After melting, these additives can quickly reduce the surface tension of the coating, promote the rapid movement of the coating before curing and film formation, and eliminate or reduce surface defects such as orange peel, brush marks, ripples, and shrinkage holes; the second is the melt viscosity of the powder coating. , under a certain shear rate (750r/min; 200r/min)S16-54 black background copper flower0.00The factors that affect the leveling of powder coatings mainly include three aspects. One is leveling aids. Appropriate leveling aids, such as silicone resins, polyacrylate resins and fluororesins, are added to the formula of powder coatings. After melting, these additives can quickly reduce the surface tension of the coating, promote the rapid movement of the coating before curing and film formation, and eliminate or reduce surface defects such as orange peel, brush marks, ripples, and shrinkage holes; the second is the melt viscosity of the powder coating. , under a certain shear rate (750r/min; 200r/min)

S16-54 black background copper flowerThe factors that affect the leveling of powder coatings mainly include three aspects. One is leveling aids. Appropriate leveling aids, such as silicone resins, polyacrylate resins and fluororesins, are added to the formula of powder coatings. After melting, these additives can quickly reduce the surface tension of the coating, promote the rapid movement of the coating before curing and film formation, and eliminate or reduce surface defects such as orange peel, brush marks, ripples, and shrinkage holes; the second is the melt viscosity of the powder coating. , under a certain shear rate (750r/min; 200r/min)S16-54 black background copper flower0.00The factors that affect the leveling of powder coatings mainly include three aspects. One is leveling aids. Appropriate leveling aids, such as silicone resins, polyacrylate resins and fluororesins, are added to the formula of powder coatings. After melting, these additives can quickly reduce the surface tension of the coating, promote the rapid movement of the coating before curing and film formation, and eliminate or reduce surface defects such as orange peel, brush marks, ripples, and shrinkage holes; the second is the melt viscosity of the powder coating. , under a certain shear rate (750r/min; 200r/min) -

9520 rose goldPowder coatings have become one of the most environmentally friendly coating systems due to their complete absence of organic solvents and low VOC (volatile organic compound) emissions during curing. According to experts from China Epoxy Resin Industry Association, electrostatic powder coatings will be developed more and more rapidly in the 21st century. In 2010, powder coatings will occupy 20% of the total industrial coatings. Optimizing the formula design and improving the construction process of powder coatings to improve their leveling performance is of great and ideal significance to its market development. In this context, a large number of discussions on dealing with the poor leveling defects of powder coatings have arisen. A study recently proposed that UV-curable powder coatings are an effective way to improve film leveling.9520 rose gold0.00Powder coatings have become one of the most environmentally friendly coating systems due to their complete absence of organic solvents and low VOC (volatile organic compound) emissions during curing. According to experts from China Epoxy Resin Industry Association, electrostatic powder coatings will be developed more and more rapidly in the 21st century. In 2010, powder coatings will occupy 20% of the total industrial coatings. Optimizing the formula design and improving the construction process of powder coatings to improve their leveling performance is of great and ideal significance to its market development. In this context, a large number of discussions on dealing with the poor leveling defects of powder coatings have arisen. A study recently proposed that UV-curable powder coatings are an effective way to improve film leveling.

9520 rose goldPowder coatings have become one of the most environmentally friendly coating systems due to their complete absence of organic solvents and low VOC (volatile organic compound) emissions during curing. According to experts from China Epoxy Resin Industry Association, electrostatic powder coatings will be developed more and more rapidly in the 21st century. In 2010, powder coatings will occupy 20% of the total industrial coatings. Optimizing the formula design and improving the construction process of powder coatings to improve their leveling performance is of great and ideal significance to its market development. In this context, a large number of discussions on dealing with the poor leveling defects of powder coatings have arisen. A study recently proposed that UV-curable powder coatings are an effective way to improve film leveling.9520 rose gold0.00Powder coatings have become one of the most environmentally friendly coating systems due to their complete absence of organic solvents and low VOC (volatile organic compound) emissions during curing. According to experts from China Epoxy Resin Industry Association, electrostatic powder coatings will be developed more and more rapidly in the 21st century. In 2010, powder coatings will occupy 20% of the total industrial coatings. Optimizing the formula design and improving the construction process of powder coatings to improve their leveling performance is of great and ideal significance to its market development. In this context, a large number of discussions on dealing with the poor leveling defects of powder coatings have arisen. A study recently proposed that UV-curable powder coatings are an effective way to improve film leveling. -

7503 rose goldFluorocarbon spraying is a kind of electrostatic spraying and liquid spraying. Here we share three common spraying methods for you. 1. Air spray mode7503 rose gold0.00Fluorocarbon spraying is a kind of electrostatic spraying and liquid spraying. Here we share three common spraying methods for you. 1. Air spray mode

7503 rose goldFluorocarbon spraying is a kind of electrostatic spraying and liquid spraying. Here we share three common spraying methods for you. 1. Air spray mode7503 rose gold0.00Fluorocarbon spraying is a kind of electrostatic spraying and liquid spraying. Here we share three common spraying methods for you. 1. Air spray mode -

PD61359 dark grey sand patternIn the current home improvement industry and stone industry, wood grain transfer processing equipment is widely used to produce various types of materials and metal panels, which can make wood products and stone achieve the desired desired effect. Since the equipment is based on the principle of physical sublimation, it can process the raw materials within a few minutes, especially the surface coating can penetrate to 60 microns inside, whether it is stone or wood, it has good adhesion and stability.PD61359 dark grey sand pattern0.00In the current home improvement industry and stone industry, wood grain transfer processing equipment is widely used to produce various types of materials and metal panels, which can make wood products and stone achieve the desired desired effect. Since the equipment is based on the principle of physical sublimation, it can process the raw materials within a few minutes, especially the surface coating can penetrate to 60 microns inside, whether it is stone or wood, it has good adhesion and stability.

PD61359 dark grey sand patternIn the current home improvement industry and stone industry, wood grain transfer processing equipment is widely used to produce various types of materials and metal panels, which can make wood products and stone achieve the desired desired effect. Since the equipment is based on the principle of physical sublimation, it can process the raw materials within a few minutes, especially the surface coating can penetrate to 60 microns inside, whether it is stone or wood, it has good adhesion and stability.PD61359 dark grey sand pattern0.00In the current home improvement industry and stone industry, wood grain transfer processing equipment is widely used to produce various types of materials and metal panels, which can make wood products and stone achieve the desired desired effect. Since the equipment is based on the principle of physical sublimation, it can process the raw materials within a few minutes, especially the surface coating can penetrate to 60 microns inside, whether it is stone or wood, it has good adhesion and stability. -

PD61359 dark grey sand pattern

PD61359 dark grey sand pattern -

7503 rose gold7503 rose gold0.00

7503 rose gold7503 rose gold0.00 -

9520 rose gold9520 rose gold0.00

9520 rose gold9520 rose gold0.00 -

S16-54 black background copper flower

S16-54 black background copper flower -

J9005 Silver flower on black background

J9005 Silver flower on black background -

8300S coffee sand grain

8300S coffee sand grain -

M22-0424 red sand pattern

M22-0424 red sand pattern -

7037 Matt light gray7037 Matt light gray0.00

7037 Matt light gray7037 Matt light gray0.00 -

7015D matt medium gray

7015D matt medium gray -

9005 black sand pattern

9005 black sand pattern

Message

Our staff will contact you in time, if you need other services, please call the service hotline:158-9572-3106

Our staff will contact you in time, if you need other services, please call the service hotline:158-9572-3106

全部评论

已有(yǒu)0条评论

There is currently no content to display

Please add data record on website background.

Yangzhou Jinmao Powder Coating Co., Ltd.

Tel:

Add:

South District, Xiaoji Industrial Park, Jiangdu District, Yangzhou City, Jiangsu Province

Copyright © 2022 Yangzhou Jinmao Powder Coating Co., Ltd. SEO

15895723106

15895723106

E-mail

E-mail