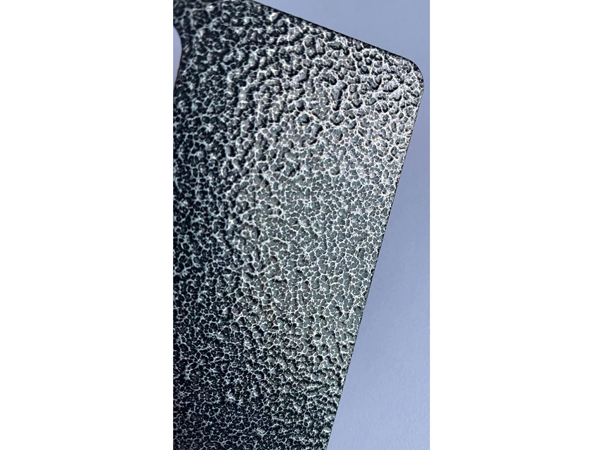

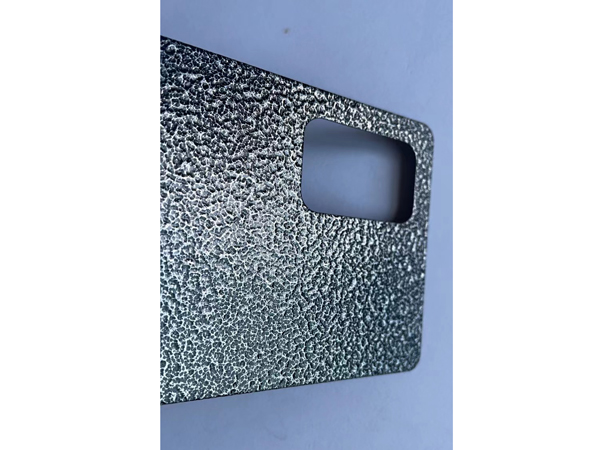

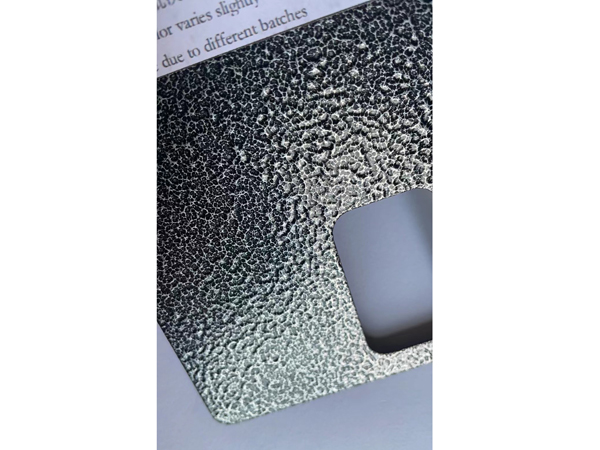

J9005 Silver flower on black background

Different from the film-forming mechanism of ordinary powder coatings, the film-forming process of UV-curable powder coatings is: heating with infrared rays or hot air to melt and level the powder coatings, and then stop the photopolymerization reaction under the irradiation of ultraviolet light, and cure to form a film. In this process, the melting process of the powder coating is completely separated from the curing process, which is easy to control and the appearance of the coating film is smooth. The industry conducted hot air curing and UV curing experiments on a powder coating system composed of amorphous methacrylic resin and two other crystalline compounds, respectively. The results show that the leveling of hot air curing is difficult to control, and UV curing The appearance of the film is smoother and the leveling is good. UV-curable powder coatings have lower melt viscosity at lower temperatures, resulting in better film-forming leveling*. UV-curable powder coatings are prepared by using different structural composite systems, that is, resins and other compounds form crystalline/amorphous or semi-crystalline, non-crystalline structural composite systems, and the crystalline component can reduce the melt viscosity and ensure its storage stability. The ingredients can adjust the level of viscosity reduction to prevent sagging when the viscosity is too low. In addition, because the star-shaped branched macromolecules do not entangle within and between molecules, and their melt viscosity is lower than that of linear polymers with the same composition and relative molecular mass, it is a more ideal resin for light-curing powder coatings, and has become a UV-curable resin. A hot topic of discussion.

PRODUCT

Yangzhou Jinmao Powder Coating Co., Ltd.

Tel:

Add:

South District, Xiaoji Industrial Park, Jiangdu District, Yangzhou City, Jiangsu Province

Copyright © 2022 Yangzhou Jinmao Powder Coating Co., Ltd. SEO

15895723106

15895723106

E-mail

E-mail